Copper Tailing (Aluminum Wiring Pigtail) Services In Ottawa

UPGRADE YOUR ELECTRICAL SYSTEM FOR SAFETY AND RELIABILITY

OTTAWA ELECTRICIAN SERVICES

Ever ready to serve your electrical services needs.

ADDRESSING AND ENSURING SAFETY

The Importance of Copper Tailing

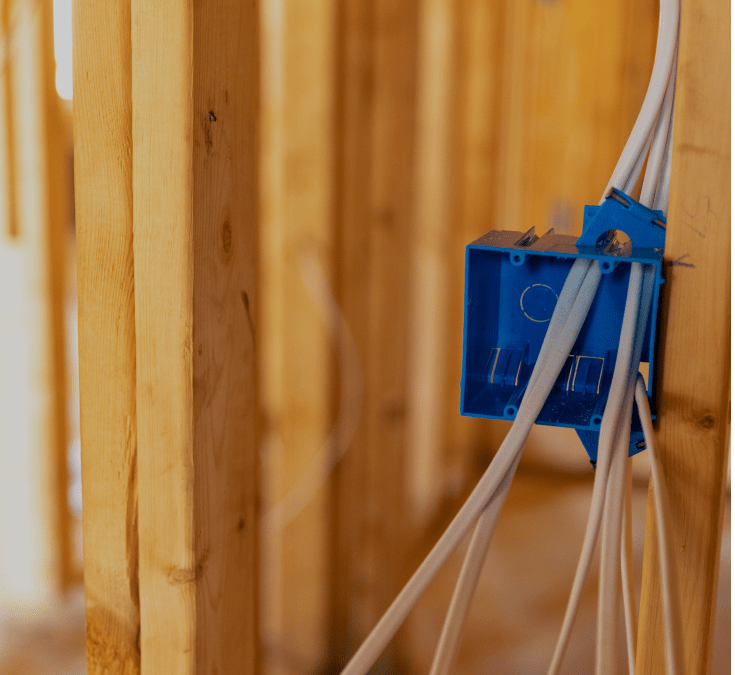

Copper tailing services play a vital role in enhancing the safety and reliability of electrical systems, particularly those with aluminum wiring. As your electrical needs evolve, ensuring your wiring is up to standard becomes crucial. Copper tailing, or aluminum wiring pigtail, is a specialized service designed to address the challenges associated with aluminum wiring by introducing copper connections.

Aluminum wiring, while once common, is now considered outdated due to its potential fire hazards. Copper tailing involves replacing or enhancing connections with copper to mitigate these risks. This service optimizes safety and reliability, providing a modern solution to the challenges posed by aging aluminum wiring.

Get Started with Us

Get in touch with the LB Electric team of experts in Ottawa. Whether you have questions about our services, want to request a quote, or need assistance with an electrical project, we are here to help.

OUR APPROACH TO COPPER TAILING

Why Choose LB Electric for Copper Tailing Services?

Expertise: Our team boasts extensive experience in addressing aluminum wiring challenges through copper tailing services.

Safety Focus: We prioritize safety in every step of the process, ensuring that your electrical system meets the highest standards.

Reliability: Copper tailing enhances the overall reliability of your electrical connections, reducing the risks associated with outdated aluminum wiring.

Seamless Process: Our professionals follow a systematic approach, from assessment to implementation, ensuring a seamless copper tailing service.

Upgrade your electrical system with confidence. Choose LB Electric for specialized copper tailing services in Ottawa. Enhance safety, mitigate risks, and ensure the reliability of your electrical connections. Contact us today for a comprehensive assessment and expert copper tailing solutions.

Frequently Asked Questions

From electrical installations to repairs and upgrades, LB Electric is here to assist you every step of the way. Don’t see the answer you’re looking for? Feel free to reach out!

- Follow Us on Instagram